|

Excavator Buckets:

Heavy Duty Bucket

Strickland Bucket

Pavement/Slab

Removal

Swinger/Tilt

Vee Bucket

Skeleton/Screening

Bucket

Screening Bucket

Cobra Screening

Bucket

Thumbs:

Universal Thumbs

T1 Excavator

The Clamp

Grapples:

Q Quality Grapple

Construction Grapple

Strickland Grapple

Super Large Grapple

Box-Style Grapple

Quick Couplers:

MM Coupler

Strickland S-Lock

Concrete Pulverizers:

Alternative Pulverizer

Strickland Pulverizer

YPC Crusher

Cracker Splitter Combos:

Strickland

Cracker/Splitter

Stump Splitters:

Ransome Stump

Splitter/Shear

Ransome

Shark Tooth

Heavy Duty

Brush Hog

Black Splitter

Tree Shear

14/20" Forestry

Stump Puller

Green Machine

Q Splitter

YST050

Stump and Asphalt Grinder

Hydraulic Grapples:

YM Grapple

YDG / YSG Grapples

Clamshell Buckets:

YC Clamshell

Cable / Wire Clam

Buckets:

Custom Large

Excavator Buckets

Roll-Out Bucket

Loader Skeleton Bucket

Brackets:

Top Bracket

Quick Coupler Bracket

Rakes:

Loader Stacking Rake

Skid Steer Grapple Rake

Skid Steer Stacking

Semi-Low Profile Dozer

Low Profile Dozer

Excavator Rake

Forks:

Pallet & Utility Forks

Bucket Forks

Heavy Duty Forks

Fork Carriage

Universal Processors:

Mini Crusher / Shear

Shears:

YSR Shear

YLS Shear

SH Shears

Mini Crushers

Diverter Valve

Hammers:

Rockblaster Hammers

Vibrating Pile Driver

Rippers:

Ransome Rippers

Misc:

Plate Compactor

Compaction Wheels

Wrecking Drop Ball

Material Handler Front

Specialty Machines:

Marsh Buggies

Small Track Dumper

Rotary Cutters

Magnets:

LGI Magnets

Quick Mags

Instant Generator/Mag

Sticks & Booms:

Long Reach Package

100k lb L/R Package

Stick Extensions

Demolition Front End

Telescoping Booms/Sticks

3rd Stick

Stretch Stick

High Reach Demolition

Custom Ultra High

Elevated Cab

Hill Hoe

|

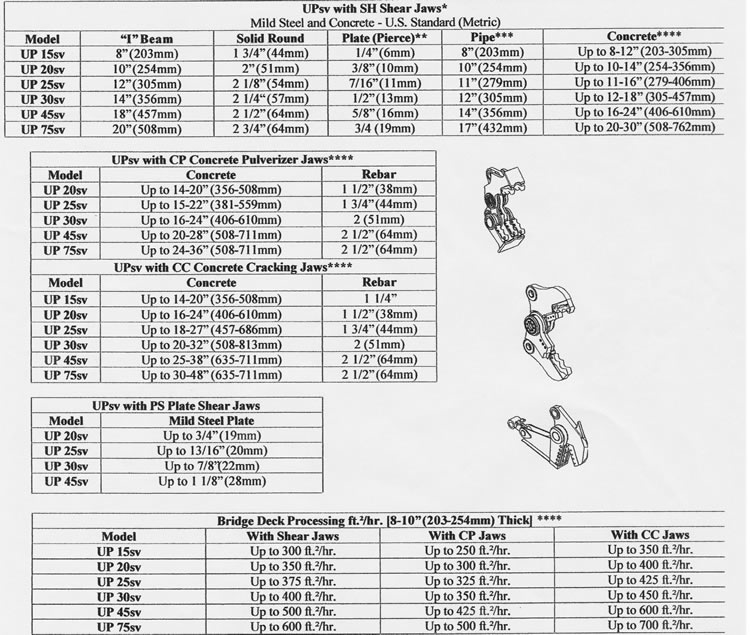

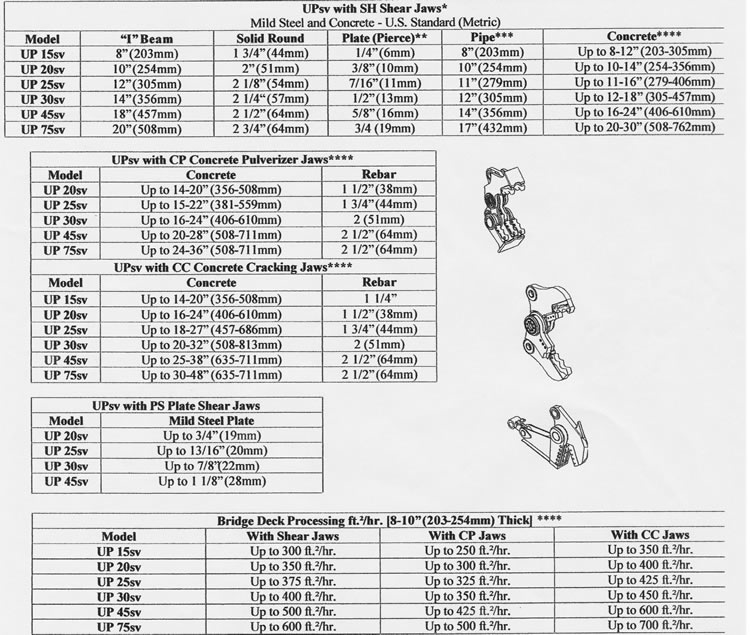

LaBounty Processor Specifications

|

| |

| UP15 Universal Processor |

| |

| Models UP 15SV/20SV/25SV/30SV/45SV/75SV/90 |

| LaBounty Universal Processors are designed to maximize the use of one attachment by using a variety of changeable jaw sets. With SIX JAW SETS to choose from one attachment can be used for concrete cracking, concrete pulverizing, scrap metal shearing, plate shearing, reinforced concrete processing, or wood shearing.

Patented changeable LaBounty Swift Lockô teeth are standard on most concrete pulverizer and concrete cracking and pulverizer Jaws. |

| |

| FEATURES: |

| The following are some of the materials that LaBounty Universal Processors are used on for demolition and/or recycling: |

| |

- "H" or "I" steel beam

- Steel Plate

- Pipe

- Rebar

- Round Stock Concrete

- Brick

- Block

- Wire

- Tires

- Tree Stumps

- Logs

- Railroad Ties

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

|

|

Download

our LaBounty Universal Processor specifications for more information:

LaBounty

UP SV Series

Download

the LaBounty Appetite Guides for the following models:

LaBounty

UP SV Series

NOTE: These specifications require Adobe Acrobat Reader to view.

Download it here.

|

HDR Grapples

| LaBounty HDR Grapples provide versatility for a wide range of uses including: demolition, scrap recycling, rip-rap, land clearing, log and pipe handling, and quarry applications. HDR Grapples feature a two-tine upper and a three-tine lower jaw configuration. |

Specifications

| Model |

Excavator Class |

Weight |

Capacity |

Opening |

Upper Jaw Width |

Lower Jaw Width |

| HDR 80* |

15-25,000 lbs |

750 lbs |

0.38-0.75 cu yds |

58" |

18" |

30.5" |

| HDR 100 |

25-35,000 lbs |

1,540 lbs |

0.75-1.25 cu yds |

88" |

20.5" |

32.5" |

| HDR 110 |

35-46,000 lbs |

2,650 lbs |

2-3 cu yds |

95" |

29.75" |

43.75" |

| HDR 120 |

46-65,000 lbs |

3,500 lbs |

2.5-3.5 cu yds |

113" |

30" |

44" |

| HDR 140 |

65-88,000 lbs |

4,850 lbs |

3.5-5.5 cu yds |

116" |

32" |

48" |

| HDR 160 |

88-111,000 lbs |

5,700 lbs |

5.5-6.5 cu yds |

142" |

34" |

52" |

| HDR 170 |

111-180,000 lbs |

7,700 lbs |

7-9 cu yds |

150" |

39" |

58" |

| Call us for pricing on all models. |

* 80 Model includes a double-acting lower jaw for better picking up and dumping action. Actual payload will depend upon materials handled.

TR Grapples

| TR Grapples, with a three-tine upper half and a four-tine lower, are the preferred method for land clearing, raking and stacking burn piles, demolishing wood and brick structures, and rehandling bulky, loose materials. |

Specifications

| Model |

Excavator Class |

Weight |

Capacity |

Opening |

Upper Jaw Width |

Lower Jaw Width |

| TR 80* |

15-25,000 lbs |

800 lbs |

0.38-0.75 cu yds |

58" |

21.5" |

30.5" |

| TR 100 |

25-35,000 lbs |

1,750 lbs |

0.75-1.25 cu yds |

88" |

23" |

32.5" |

| TR 110 |

35-46,000 lbs |

2,700 lbs |

2-3 cu yds |

95" |

30" |

44" |

| TR 120 |

46-65,000 lbs |

3,500 lbs |

2.5-3.5 cu yds |

113" |

30" |

44" |

| TR 140 |

65-88,000 lbs |

4,900 lbs |

3.5-5.5 cu yds |

116" |

33" |

48" |

| TR 160 |

88-111,000 lbs |

6,000 lbs |

5.5-6.5 cu yds |

142" |

36.75" |

52" |

| TR 170 |

111-180,000 lbs |

8,000 lbs |

7-9 cu yds |

150" |

47" |

68" |

| Call us for pricing on all models. |

* 80 Model includes a double-acting lower jaw for better picking up and dumping action. Actual payload will depend upon materials handled.

TW Grapples

| TW Grapples are designed for versatility with a four-tine upper half and a five-tine lower. This grapple has proven itself as a preferred method for handling waste, refuse, and large volumes of loose materials.. |

Specifications

| Model |

Excavator Class |

Weight |

Capacity |

Opening |

Upper Jaw Width |

Lower Jaw Width |

| TW 80* |

15-25,000 lbs |

850 lbs |

0.38-0.75 cu yds |

58" |

27.75" |

36" |

| TW 100 |

25-35,000 lbs |

1,600 lbs |

1-2 cu yds |

88" |

32.5" |

42" |

| TW 110 |

35-46,000 lbs |

2,750 lbs |

3-4 cu yds |

95" |

42" |

54.25" |

| TW 120 |

46-65,000 lbs |

3,550 lbs |

3.5-5.5 cu yds |

113" |

42" |

54.5" |

| TW 140 |

65-88,000 lbs |

4,800 lbs |

4-6 cu yds |

116" |

46" |

59.5" |

| TW 160 |

88-111,000 lbs |

5,800 lbs |

6-8 cu yds |

142" |

50" |

64.5" |

| TW 170 |

111-180,000 lbs |

7,800 lbs |

9-12 cu yds |

150" |

65" |

84" |

| Call us for pricing on all models. |

* 80 Model includes a double-acting lower jaw for better picking up and dumping action. Actual payload will depend upon materials handled.

All LaBounty grapples offer:

|

| · Box tine Construction provides strength and rigidity to withstand the full breakout force of the excavator on each tine. |

| · Heavy-duty Mounting Lugs greatly reduce wear on bearings fro side loads during grapple operation. |

| · Spools join halves of the grapple, even when the main pivot pin is removed, amking grapple mounting and dismounting simple. |

| · Optional Wear Kits are available for extremely abrasive applications. |

| · Replacable Hardened Tine Tips for increased wearability and reduced downtime for hard surfacing. |

| · Hardened Man Pin inserted in spool. Bearings in upper jaw rotate on spools, not on the pin, greatly reducing pin wear and breakage. |

| · Compatable with many quick coupling systems. (Note: Quick couplers can alter the grapple specs.) |

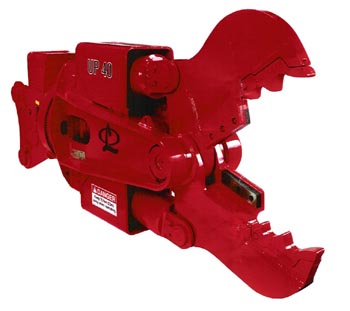

| LaBounty Universal Processors |

|

| Univerals Processors allow various jaw options for maximum equipment utilization. Universal Processors are ideal for demolition, road and bridge reconstruction and concrete recycling operations. |

| UP15 Universal Processor |

| |

| Models UP 15SV/20SV/25SV/30SV/45SV/75SV/90 |

| LaBounty Universal Processors are designed to maximize the use of one attachment by using a variety of changeable jaw sets. With SIX JAW SETS to choose from one attachment can be used for concrete cracking, concrete pulverizing, scrap metal shearing, plate shearing, reinforced concrete processing, or wood shearing.

Patented changeable LaBounty Swift Lockô teeth are standard on most concrete pulverizer and concrete cracking and pulverizer Jaws. |

| |

| FEATURES: |

| The following are some of the materials that LaBounty Universal Processors are used on for demolition and/or recycling: |

| |

- "H" or "I" steel beam

- Steel Plate

- Pipe

- Rebar

- Round Stock Concrete

- Brick

- Block

- Wire

- Tires

- Tree Stumps

- Logs

- Railroad Ties

|

| |

|

| |

|

| |

|

|

|

|

Specifications

| Model |

Excavator Class |

Available Jaw Sets |

Weight |

Jaw Opening |

Jaw Depth |

Reach |

| UP 4 |

Mini Excavators |

Shear

Concrete Cracking |

525 lbs

525 lbs |

6.7"

13.5" |

6.7"

6.6" |

3' 9"

3' 9" |

| UP 20 |

24,000 lbs |

Shear

Concrete Pulverizer

Concrete Cracking

Plate Shear

Wood Shear |

4,100 lbs

4,300 lbs

4,550 lbs

4,100 lbs

4,100 lbs |

20"

25"

38"

9"

37" |

18"

20"

28"

11"

26" |

6' 4"

6' 4"

6' 4"

6' 4"

6' 4" |

| UP 40 |

42,000 lbs |

Shear

Concrete Pulverizer

Concrete Cracking

Plate Shear |

6,500 lbs

7,000 lbs

7,000 lbs

6,000 lbs |

24"

31"

43"

14" |

21"

23"

34"

16" |

9'

9'

9'

9' |

| UP 50 |

52,000 lbs |

Shear

Concrete Pulverizer

Concrete Cracking

Plate Shear |

9,200 lbs

9,700 lbs

10,000 lbs

9,200 lbs |

27"

36"

51"

16" |

24"

27"

42"

20" |

12' 6"

12' 6"

12' 6"

12' 6" |

| UP 70 |

68,000 lbs |

Shear

Concrete Pulverizer

Concrete Cracking

Plate Shear |

11,500 lbs

12,500 lbs

12,500 lbs

9,570 lbs |

36"

48"

62"

21" |

30"

35"

46"

24" |

14'

14'

14'

14' |

| UP 90 |

100,000 lbs |

Shear

Concrete Pulverizer

Concrete Cracking |

16,600 lbs

17,500 lbs

18,000 lbs |

42"

60"

72" |

31"

38"

44" |

13'

13'

13' |

| Call us for pricing on all models. |

| · Standard 360° powered rotation allows for efficient processing at any angle. |

| · Up to six jaw sets are available per model and can be changed out in as little as 20 minutes. |

| · Swift Lock™ Tooth System is standard equipment on most Concrete Pulverizer and Concrete Cracking Jaws. |

| · Multiple-machine mounting brackets are available for some excavators, allowing the UP to mount to several excavator mounts within the same weight class. |

Swift Lock™ Replacable Tooth system |

|

| Swift Lock teeth are standard equipment on most Labounty Concrete Cracking and Pulverizer Jaws. These exclusive, patented pin-on replacable teeth allow end-users to change out teeth on attachments in the field in minutes. This system significantly reduces down-time otherwise necessary for routine build-up and hardsurfacing. |

Six Jaw Sets to Choose From ...

|

Concrete Cracking Jaws - The large opening of this jaw set is excellent for breaking large concrete structures - parapets, pillars, beams and applications where the contractor wants the structure leveled with maximum safety and efficiency. |

|

Concrete Pulverizer Jaws - Use this jaw set as a primary demplition tool, separating concrete and rebar as it works; or as a secondary tool, processing material once it is on the ground. |

|

Shear Jaws - Though not designed for full-time scrap metal processing, the shear jaws are excellent for processing steel encountered on demolition sites like rebar structural steel, etc. |

|

Plate Shear Jaws - For processing both above and below-ground storage tanks. The Plate shear Jaw cuts plate cleanly, reducing the amount of material distortion, providing denser loads and greater salvagability. |

|

Demolition Jaws - Ideal for demolition applications where the combined features of the Shear Jaw and concrete Cracking Jaw allow it to process heavily reinforced concrete structures and concrete encased I-beams without jaw change. |

|

Wood Shear Jaws - This highly productive jaw set is designed for downsizing all types of wood products such as stumps, logs and wood demolition debris. |

Appetite Guides

| UP with Concrete Cracking Jaws |

| Model |

Concrete |

Rebar |

| UP 20 |

24" |

1 1/4" |

| UP 40 |

30" |

1 1/2" |

| UP 50 |

36" |

1 3/4" |

| UP 70 |

42" |

2" |

| UP 90 |

48" |

2 1/4" |

|

| UP with Concrete Pulverizer Jaws |

| Model |

Concrete |

Rebar |

| UP 20 |

18" |

1" |

| UP 40 |

22" |

1 1/4" |

| UP 50 |

26" |

1 1/2" |

| UP 70 |

30" |

1 3/4" |

| UP 90 |

36" |

2" |

|

| UP with Shear Jaws |

| Model |

I-beam |

Solid round |

Plate |

Pipe |

Concrete |

| UP 20 |

10" |

2" |

3/8" |

10" |

14" |

| UP 40 |

12" |

2 1/4" |

7/16" |

12" |

16" |

| UP 50 |

16" |

2 1/2" |

5/8" |

14" |

20" |

| UP 70 |

18" |

2 3/4" |

3/4" |

16" |

28" |

| UP 90 |

21" |

3" |

7/8" |

18" |

32" |

|

| UP with Plate Shear Jaws |

| Model |

Mild Steel Plate |

| UP 20 |

5/8" |

| UP 40 |

3/4" |

| UP 50 |

1" |

| UP 70 |

1 1/4" |

|

| UP with Demolition Jaws |

| Model |

Concrete |

I-beam |

Solid Round |

| UP 20 |

20" |

8" |

2" |

| UP 40 |

24" |

16" |

2 1/4" |

| UP 50 |

27" |

18" |

2 1/2" |

|

| UP with Wood Shear Jaws |

| Model |

Lag Diameter |

| UP 20 |

24" |

| UP 40 |

28" |

| UP 50 |

32" |

|

| Shear Jaw Outline |

|

Concrete Pulverizer Jaw Outline |

|

By using a shear or universal processor suspended from a crane, you can go to ALMOST any height needed

|

| Ransome Equipment Sales, LLC |

| 106 Ark Road, Lumberton, NJ 08048 |

| Phone: 609-975-8127 Fax: 609-257-3719 |

| E-mail: sales@ransome-equip.com |

|